Description

Irrigation Powertrain – Centre Drives substitute OMNI gear IR-922, IR-15,IR-twenty

Irrigation Powertrain – Middle Drives alternative OMNI gear IR-922, IR-15,IR-20

Software for: Feed Blenders, Flail Mowers, Potato Harvesters, Pump Drives, Rock Pickers

Central pivot irrigation program reduction motor

20:1 ratio eleven/2HP

25:1 ratio 1 1/2HP

thirty:1 ratio eleven/2HP

40:1 ratio 3/4HP

50: 1 ratio 3/4HP

60:1 Ratio 3/4HP

Reduction motors for heart pivot irrigation systems provide 3-phase,460/380 VOLT AC,60/fifty Hz motors or single-phase,60/fifty Hz motors. We give multi-velocity ratio, decelerating gearboxes, employing ninety five% effectiveness helical spur gears to transfer power to the last generate equipment bins. * Spray protection include can improve dampness protection when the nozzle is positioned underneath the reduction motor. * Supplies a few-section, solitary-stage, and inverter load applications. * Aluminum fin stator housing, low functioning temperature. * Helical gear spur equipment design offers a selection of transmission ratios. * All aluminum gearbox, reduce functioning temperature, prolonged service existence, increased corrosion resistance. * bolt set up mode far more appropriate for “x63/8” (33/8), (forty three/4 “x71/4”), and “x6” (5) bolt sample. * All gears are warmth taken care of. * Voltage: 460V 60Hz, 380V 50Hz and 208-230V 60Hz, 220-240V 50Hz thermal defense, automatic reset is located in the very easily accessible junction box. * Specifically designed input and output seals. * Top fill plug is positioned to set proper oil degree. * All crucial electrical connections are sealed with. handles and guarded from dampness. * Course H conductors and course F insulation. * TFE lines on all magnetic wire to motor guide connections. * Scaled-down turbines and smaller incoming line measurements can be utilized. * Performance:ninety five%. F Stainless metal junction box protect. F Double shaft seals.

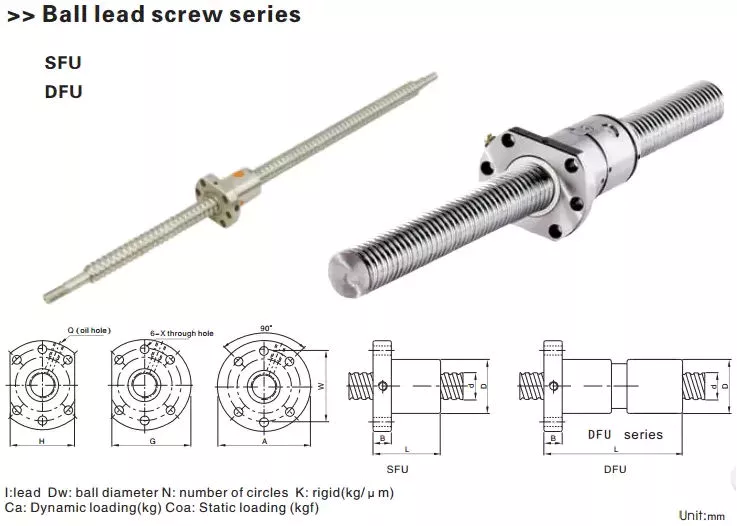

Specifying a Ball Screw

When you want a large-high quality ball screw, it is crucial to select one with the correct proportions and specifications. When you are looking for the best item, you should contemplate characteristics this kind of as preloading, floor complete, and inner return method. You can understand far more about these attributes in this report. If you might be not sure which kind of ball screw to choose, speak to a respected supplier for more direction. To discover the very best solution for your requirements, simply click below!

Brinelling

When specifying a Brinelling ball screw, it is critical to know how a lot axial load it can safely and securely bear. The static load ability, which is provided in the catalogue, applies only to pure axial loading, and any radial load that is smaller sized than 5% of the axial load won’t pose a difficulty. For more data, get in touch with a CZPT engineer. Brinelling ball screw service existence calculation need to be done utilizing the pursuing info:

Preload: The quantity of load a ball screw can manage for the duration of a single revolution. Preload is the load used just before the ball screw starts off relocating, and the load is usually between 5 and 10 percent of the dynamic potential. Nevertheless, a ball screw that is topic to vibration will experience larger preload, necessitating far more repeated lubrication. The resulting mechanical anxiety could lead to the ball screw to buckle, or cause the nut to re-circulate the balls.

Essential ball pace: The optimum pace at which the ball can shift by way of the ball nut is called the critical ball speed. In contrast, operating the ball screw at its critical shaft speed can guide to too much vibrations, major to premature failure of the end support bearings and brinelling of the ball keep track of. As a result, it is suggested to operate a ball screw at a reduce speed than the essential ball pace to avert brinelling and plastic deformation of the balls.

Bogus brinelling: False brinelling is a sort of Fretting. False brinelling occurs when the bearings are not rotating. The movement will outcome in depressions or put on marks in the bearing raceway. This will result in sound, use, and eventual fatigue. If these situations persist, a more recent ball screw must be used to test the system. The machine ought to be run for many hrs and analyzed ahead of changing the bearing.

Preloading

The method of preloading ball screws minimizes backlash by making use of force to the threads in the opposite course of the screw’s direction of rotation. It prevents any motion of the screw relative to the nut. Different strategies are used for preloading. A frequent one is to use oversized balls within the ball nut. A double nut technique may also be used. The two methods are equally efficient. No matter of the method utilized, the stop outcome is the exact same – minimal backlash and elevated performance.

In the traditional strategy of preloading ball screws, the motors work at the same time in reverse instructions, creating them to have a relative motion of about equivalent magnitudes. This reduces the frictional resistance of the method, ensuing in rapid traverse. The program is ready to function with small backlash during one hundred ten inches of vacation, minimizing the heat produced by the generate nuts and the troubles related with ball screw heating. In addition, this approach can be utilised in a broad selection of purposes.

An additional method of preloading ball screws is identified as the ball-select method. This strategy involves the use of over-sized balls that drive the balls into more contacts with the screw and nut than a regular ball screw. The benefit of this strategy is that it minimizes backlash because the balls are not machined to higher tolerances. The downside of this approach is that the ball screw will value much more to manufacture than a standard ball screw and nut.

A conventional layout contains a mechanical mechanism that employs a series of balls to rotate a shaft. The issue of backlash is exacerbated by the mass of the shaft. The mechanical technique is a lot more complicated than needed and typically needs a great deal of energy. The current creation eliminates these difficulties by supplying an enhanced technique and equipment for driving ball screws. This technique offers a a lot more efficient preload power that is dynamically adjustable while the system is running. The method can also boost friction and dress in.

Internal return program

There are two diverse sorts of ball screws. The very first type is exterior and the 2nd is interior. The exterior variety employs return tubes that protrude from the ball nut and prolong earlier mentioned and all around the outside of the screw. The internal variety utilizes a one tube that spans the ball track, while the much more frequent layout utilizes multiple tubes spanning 1.5 to 3.5 ball tracks. The interior system involves a one return tube and numerous pickup fingers that guidebook the balls into the tubes.

The external return tube design and style is an less complicated, significantly less pricey choice. The external ball return system has constrained room but can take care of a broad assortment of shaft diameters and sales opportunities. Nonetheless, its bodily measurement can make it incompatible with numerous high-speed purposes. As a result, watchful thing to consider need to be provided to the mounting alternatives. Internal ball return systems are ideal suited for tiny sales opportunities and ball measurements. Individuals that need a large pace will most likely gain from the exterior ball return system.

Inner ball screw engineering has also held pace with the requires of linear drive methods. Ball screw engineering is now more sturdy than at any time. Sturdy inner ball return methods flow into ball bearings through a sound pickup pin. These deflectors help the balls return to the screw in the correct location. They are essential factors in computer-managed motion handle methods and wire bonding. If you’re interested in the latest advances in linear screw technologies, make contact with us right now.

Ball screws are excellent to direct screws in many methods. Ball screws are much more effective than lead screws, changing ninety% of rotational motion into linear motion. As a end result, they are much more costly than guide screws and acme screws. They also offer a smoother movement more than the whole travel selection. Additionally, they need significantly less power for the same overall performance. It’s no wonder that the ball screw is so popular in numerous various apps.

Area end

The surface area finish of a ball screw is 1 of the important elements in identifying the overall performance of the system. A ball screw with a great surface finish has excellent performance in rolling resistance, backlash, and wear qualities. However, it is vital to increase the area end of a ball screw to attain precision motion, lower use, and minimal noise. To attain this, particular wire brushes will be employed to polish precision-floor shafts.

For a ball screw to perform effectively, it should be tough, have a clean area, and keep lubricant. The surface end of a ball screw must be easy, free of cracks, and retain the lubricant effectively. Cracks and annealing are the two undesirable throughout the production approach, so a high quality equipment ought to be employed for its surface area complete. During the generation method, a CBN chopping insert with full round or gothic arch profile can be employed to obtain a substantial-quality surface end.

One more ending procedure employed in the manufacture of ball screws is lapping. Lapping improves floor good quality and journey variation. It requires complicated relative actions of abrasive particulates with the workpiece. This removes a slim layer of material from the workpiece, improving its area good quality and dimensional precision. The lapping approach can be carried out beneath minimal-strain conditions. It also boosts the friction torque and lubrication.

In lapping experiments, friction torque has the greatest influence on travel variation and surface area roughness. A friction torque of about a single N x m is the best possible. In addition, rotational pace has only a minimal influence. The greatest mixture of these parameters is 1-1.5 N x m and thirty rpm. The minimal surface end of a ball screw is all around 800 mesh. The smallest variation in journey is observed at close to 50 %-way through the vacation.

Lubrication

Proper lubrication of ball screw assemblies is vital to maintain ideal performance and life. Ball screw assemblies need to be lubricated with grease, which is launched right into the ball nut. The lubrication port can be situated at numerous spots on the item, including on the flange or in the external threads of the ball nut. Some ball nuts also feature a zerk fitting for easier lubrication.

The lubrication of ball screws is needed in the case of functioning problems in excess of 100oC. The least load for a ball screw is normally recognized with a preload force. The lubricant is conveyed by means of the narrow lubrication hole owing to the relative motion of the two surfaces. The increased viscosity of the lubricant permits separation of the speak to surfaces. To avoid over-lubrication, it is crucial to verify the lubricant level frequently.

The oil employed in lubrication of ball screw assemblies can be either mineral or synthetic. The oil is composed of mineral or synthetic oil, additives, and a thickening agent, such as lithium or bentonite. Other thickening agents incorporate lithium, barium complexes, or aluminum. The lubricant grade NLGI is a extensively utilized classification for lubricating greases. It is not sufficient to decide on a distinct type of lubricant for a specific application, but it offers a qualitative evaluate.

Even with currently being crucial to the functionality of a ball screw, lubrication is also essential to its lifespan. Different types of lubricant offer corrosion protection. Ahead of utilizing a lubricant, make positive to totally clear and dry the ball screw. If there is any buildup of dust, it could hurt the screw. To avert this from occurring, you can use a solvent or lint-free of charge cloth. Lubrication of ball screw assemblies can greatly prolong the daily life of the assembly.